When it comes to cooling garments, effective cooling is not achieved by a one-size-fits-all solution. Real cooling performance depends on a deep understanding of the user’s actual working environment and specific safety requirements. Temperature, humidity, ventilation conditions, as well as flame-retardant and anti-static standards, all play a critical role in how a cooling garment should be designed and configured.

Cooling Performance Depends on Real Environmental Conditions

In industrial and professional workplaces, cooling needs vary significantly. A high-temperature and high-humidity environment requires a completely different cooling approach compared to a dry, well-ventilated area. In poorly ventilated spaces, for example, passive cooling methods may be insufficient, while in environments with airflow, evaporative or phase-change technologies can be highly effective.

That is why cooling garments must be engineered based on:

Ambient temperature

Relative humidity

Airflow and ventilation conditions

Duration of continuous work

Intensity of physical activity

Each of these factors directly influences how heat is absorbed, transferred, and released from the human body.

Different Environments Require Different Cooling Technologies

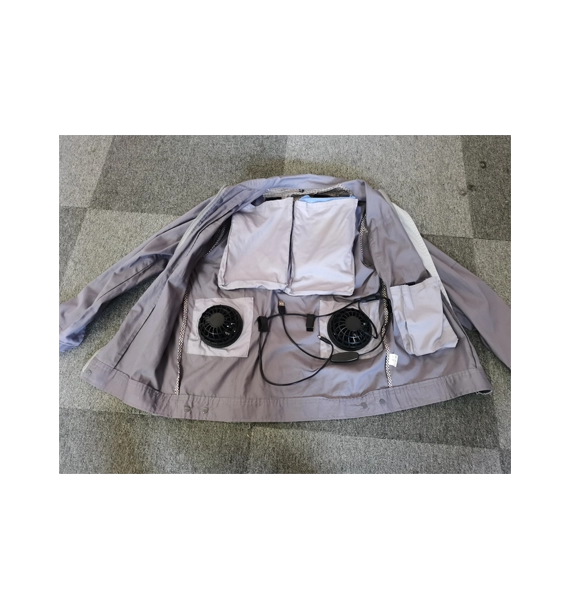

The effectiveness of cooling garments relies heavily on selecting the right cooling technology for the specific application. Depending on environmental conditions and user needs, different solutions may be applied, such as:

Phase change cooling systems for stable and controlled temperature reduction

Active cooling solutions for extreme heat exposure

Hybrid cooling designs that balance comfort, mobility, and cooling duration

Using the wrong technology in the wrong environment can lead to insufficient cooling, reduced comfort, or even safety risks. That is why professional assessment and customization are essential.

Safety Requirements Matter as Much as Cooling

In many industrial scenarios, cooling garments must meet additional safety standards. Flame-retardant, anti-static, and other protective requirements cannot be compromised for cooling performance. Instead, cooling solutions must be integrated into certified protective clothing materials without affecting compliance or durability.

This balance between thermal comfort and workplace safety requires specialized design experience and material expertise.

Customized Cooling Solutions for Maximum Effectiveness

Rather than offering generic products, professional cooling garment solutions should be designed around the user, not the other way around. By analyzing the customer’s working conditions and safety requirements, the cooling system, garment structure, and materials can be optimized to deliver the best possible cooling effect and wearing comfort.

This customized approach ensures:

Effective and consistent cooling

Improved worker comfort and productivity

Compliance with industry safety standards

Longer service life and better overall performance

Your Professional Cooling Garment Manufacturer

Suzhou SenJoy Cooling Clothing Garment Co., Ltd. is a professional cooling garment manufacturer specializing in customized cooling solutions for demanding working environments. With a comprehensive range of cooling garment systems and technologies, we provide tailored solutions designed to match real-world conditions and customer-specific requirements.

From environment analysis to technology selection and final garment design, SenJoy delivers cooling solutions that work where it matters most — on the job.