In high-temperature industrial environments, keeping workers safe and comfortable is a critical challenge. The vortex tube air conditioner waistcoat provides an innovative solution by using compressed air to deliver instant cooling without the need for electrical power, refrigerants, or complex machinery. Designed for workers in factories, steel plants, foundries, and outdoor construction, this cooling waistcoat significantly reduces heat stress and improves productivity.

The Science Behind the Vortex Tube

At the core of this cooling waistcoat lies the vortex tube, a unique device capable of separating compressed air into hot and cold streams. The process works as follows:

Compressed Air Inlet: Compressed air enters the vortex tube tangentially into the chamber, creating a rapidly rotating airflow.

High-Speed Rotation: Inside the tube, the air spins at extreme speeds.

Temperature Separation: Due to centrifugal force, the outer layer of air molecules moves faster, gaining energy and becoming hotter, while the inner core slows down, losing energy and becoming colder.

Controlled Exhaust: By adjusting the valve on the hot air exhaust, the operator can control the ratio of hot to cold air, thereby regulating the temperature of the cooling airflow.

This phenomenon allows the vortex tube air conditioner waistcoat to generate a stream of cold air instantly, delivering effective cooling directly to the wearer.

Application in Cooling Waistcoats

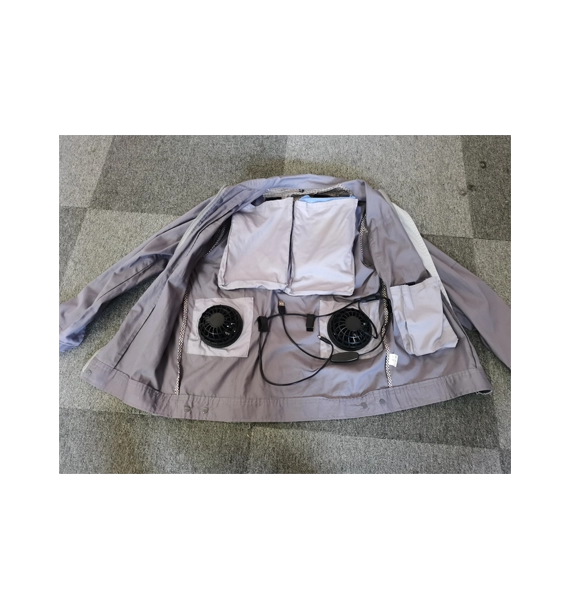

The vortex tube cooling waistcoat integrates this technology into a lightweight, wearable garment.

Cooling Distribution: Cold air produced by the vortex tube is distributed through internal air channels within the vest, covering the torso and vital areas of the body.

Adjustable Cooling: Users can easily adjust the airflow and cooling intensity depending on the working conditions.

Non-Electric Operation: Since it requires only compressed air, there are no moving parts, electrical circuits, or refrigerants, making it safe for hazardous environments.

Advantages of the Vortex Tube Air Conditioner Waistcoat

Instant Cooling: Provides immediate temperature reduction for the wearer.

Durability: With no moving parts, the vortex tube is highly reliable and requires minimal maintenance.

Portability: The waistcoat design allows workers to remain mobile and comfortable while receiving continuous cooling.

Safety in Explosive Environments: Ideal for industries where electrical cooling systems may pose a fire or explosion risk.

Industrial Applications

The vortex tube air conditioner waistcoat is widely used in:

Steel and Foundry Plants: Protecting workers exposed to extreme furnace heat.

Chemical and Petrochemical Plants: Safe cooling in potentially flammable environments.

Construction and Mining: Providing relief to workers exposed to direct sunlight or underground heat.

Maintenance and Welding Operations: Reducing heat stress during physically demanding tasks.

The vortex tube air conditioner waistcoat is a breakthrough in personal cooling technology, harnessing the physics of high-speed airflow to create an effective, safe, and maintenance-free cooling system. By separating compressed air into hot and cold streams, the vortex tube delivers instant refrigeration without electricity or chemicals. For industries facing extreme temperatures, Suzhou SenJoy Cooling Clothing Garment Co., Ltd. offers reliable cooling waistcoats that improve worker safety, comfort, and efficiency.